MATERIALS HANDLING

Chute Design and Manufacture

The design of a chute is instrumental in the way materials are loaded and unloaded from chutes. An incorrect trajectory and flow of the material will lead to blockages, premature wear of the chute and conveyor belt. That’s why HV Engineers use computer software and years of experience to design chutes that provide the optimum trajectory and coal flow for an increased life. We can also improve the design of your existing chute to increase efficiency and reduce down time.

CONVEYOR DESIGN

HV Engineers has many years of experience in the design of conveyors in all areas of materials handling. Our engineers use computer design packages such as Helix Delta T to assist in the design of the conveyor system.

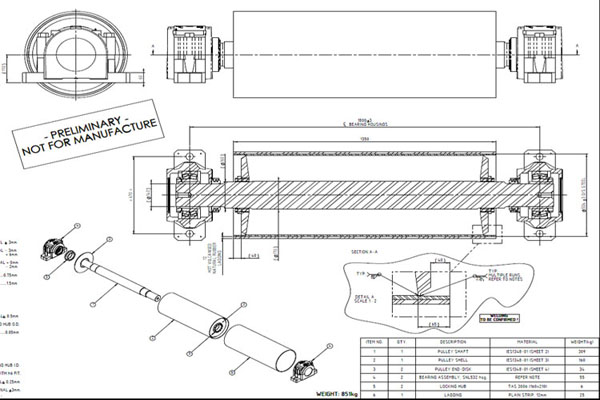

Pulleys

HV Engineers design and supply pulleys to service the mining and other industries.

The pulleys we supply are generally welded together using welding rotators and robotic equipment to ensure a high quality welding process.

After completion each pulley is tested to ensure that they are completely balanced and fit for purpose.

Lagging of pulleys in rubber, ceramic or FRAS rated material is done to customers specification or we can suggest the best lagging for your application.

Knife Gate Valves

Knife gates are a vital part of controlling the transfer of materials from chutes on to conveyors, stock piles, trains and trucks. They have to be robust and reliable to meet the harsh conditions that they are put under during operation. HV Engineers can design and build a knife gate to suit any application, whether the controlling device is an electric actuator or hydraulic cylinder.

Benefits

- Hydraulics or Electric Cylinder actuators

- Easy to clean

- Easy to inspect and maintain

- Long life HDPE sliders

- Solid stainless steel gates

- Precision machined components

Applications

- Storage Bins

- Hoppers

- Reclaim chutes

- Coal Blending